English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

The Critical Role of Oil Filters in Heavy

2025-02-17

The Critical Role of Oil Filters in Heavy-Duty Trucks: Ensuring Performance and Reliability

Heavy-duty trucks are the workhorses of the transportation industry, carrying goods across long distances and through challenging terrains. To ensure these vehicles operate efficiently and reliably, proper filtration systems are essential. Among the most critical components are oil filters, heavy-duty truck filters, and hydraulic filters. This article explores their functions, types, and benefits, highlighting their importance in the heavy-duty trucking sector.

What is an Oil Filter?

An oil filter is a device designed to remove contaminants from engine oil, transmission oil, or lubricating oil. Its primary function is to ensure that the oil circulating within the engine is free from impurities such as dirt, metal particles, and sludge. Clean oil is essential for reducing friction, preventing wear and tear, and maintaining the efficiency of the engine.

Key Functions of Oil Filters

1. Contaminant Removal: Captures harmful particles that can damage engine components.

2. Lubrication Enhancement: Ensures smooth oil flow, reducing friction between moving parts.

3. Temperature Regulation: Helps maintain optimal oil temperature by preventing clogging and ensuring proper circulation.

Heavy-Duty Truck Filters: Built for Tough ConditionsHeavy-duty truck filters are specifically designed to meet the demanding needs of large commercial vehicles, such as semi-trucks, dump trucks, and freight carriers. These vehicles operate in harsh environments, including dusty highways, muddy construction sites, and extreme weather conditions, making robust filtration systems a necessity.Features of Heavy-Duty Truck Filters4. High Durability: Built to withstand extreme conditions, including high temperatures and heavy loads.

5. Enhanced Filtration Efficiency: Capable of capturing finer particles to protect sensitive engine components.

6. Extended Service Life: Designed to last longer, reducing the frequency of replacements and maintenance downtime.

Applicationsl

● Semi-Trucks: Protect engines during long-haul journeys, ensuring consistent performance.

● Dump Trucks: Ensure clean oil flow in engines operating in dusty and muddy environments.

● Freight Carriers: Maintain lubrication in critical components to prevent breakdowns during heavy loads.

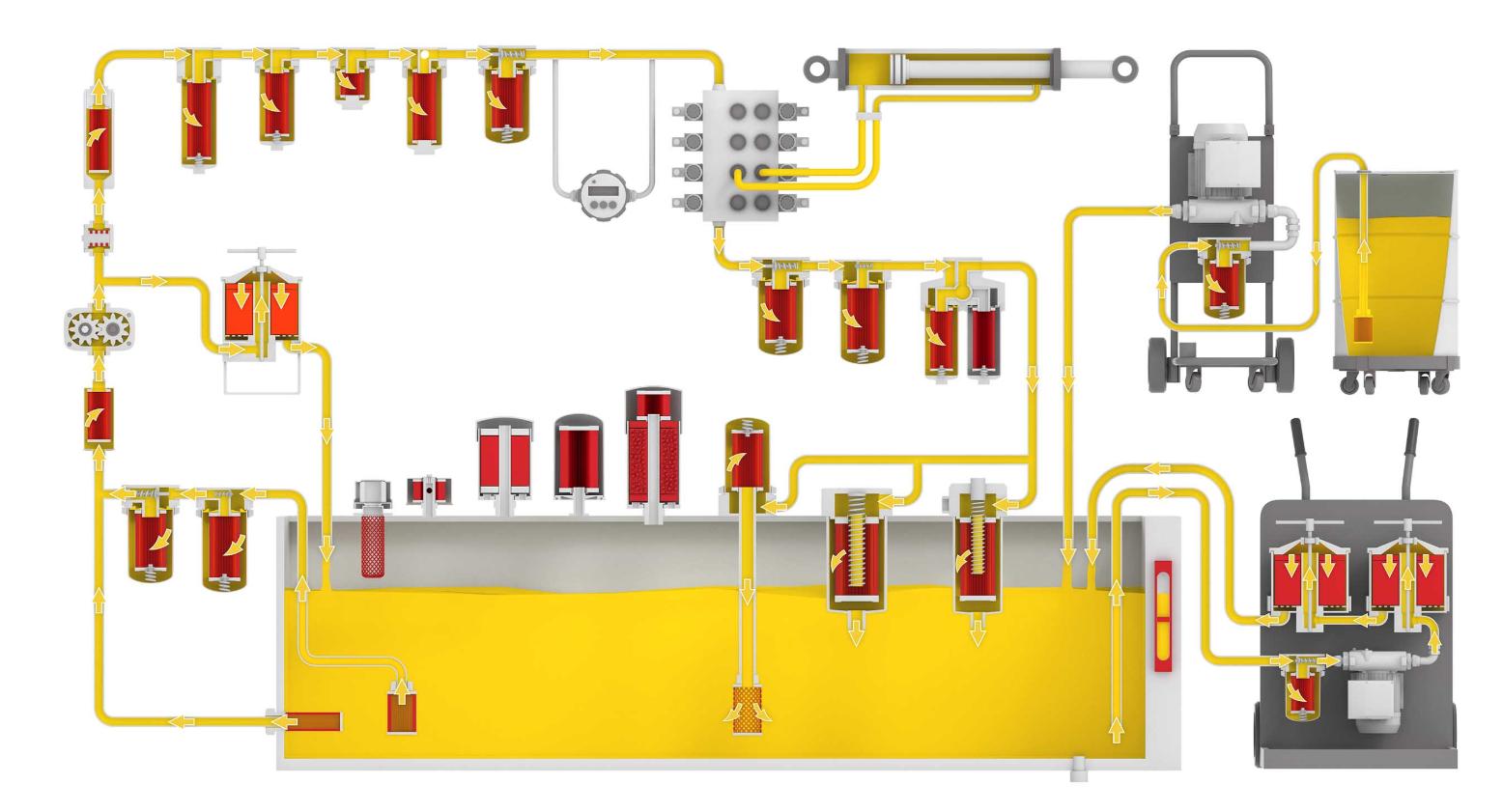

Hydraulic Filters: The Backbone of Hydraulic Systems in Heavy-Duty Trucks

Hydraulic filters play a vital role in maintaining the efficiency and longevity of hydraulic systems, which are integral to many heavy-duty trucks. These systems rely on hydraulic fluid to transmit power, and any contamination can lead to system failure.

Functions of Hydraulic Filters

1. Contaminant Removal: Filters out particles that can damage hydraulic pumps, valves, and cylinders.

2. Fluid Cleanliness Maintenance: Ensures the hydraulic fluid remains clean, preventing system malfunctions.

3. Pressure Regulation: Helps maintain consistent hydraulic pressure, which is crucial for smooth operation.

Types of Hydraulic Filters

4. Suction Filters: Installed at the hydraulic pump inlet to prevent large particles from entering the system.

5. Pressure Filters: Placed in the pressure line to protect downstream components from fine contaminants.

6. Return Line Filters: Clean the fluid before it returns to the reservoir, ensuring overall system cleanliness.

Why Are These Filters Important for Heavy-Duty Trucks?

1. Extended Vehicle Lifespan

By removing harmful contaminants, oil filters and hydraulic filters reduce wear and tear on critical components, significantly extending the lifespan of heavy-duty trucks.

2. Improved Performance

Clean oil and hydraulic fluid ensure that trucks operate at peak efficiency, providing consistent power and reducing the risk of unexpected breakdowns.

3. Cost Savings

Regular use of high-quality filters minimizes the need for costly repairs and replacements, saving both time and money in the long run.

4. Environmental Benefits

Proper filtration reduces the emission of harmful pollutants by ensuring efficient combustion and reducing oil consumption.

Choosing the Right Filter for Your Heavy-Duty Truck

When selecting an oil filter, heavy-duty truck filter, or hydraulic filter, consider the following factors:

● Compatibility: Ensure the filter is designed for your specific truck model and application.

● Filtration Efficiency: Look for filters with high micron ratings to capture finer particles.

● Durability: Choose filters made from robust materials that can withstand harsh operating conditions.

● Ease of Maintenance: Opt for filters that are easy to install and replace to minimize downtime.

Conclusion

In the world of heavy-duty trucks, oil filters, heavy-duty truck filters, and hydraulic filters are more than just accessories—they are essential components that ensure the smooth operation and longevity of commercial vehicles. By investing in high-quality filtration systems, truck operators can enhance performance, reduce maintenance costs, and extend the life of their vehicles. Whether you're operating a semi-truck, dump truck, or freight carrier, the right filter can make all the difference in keeping your vehicle running at its best.

This article highlights the importance of filtration systems in heavy-duty trucks, emphasizing their roles, benefits, and selection criteria. By understanding the value of oil filters, heavy-duty truck filters, and hydraulic filters, truck operators can make informed decisions to optimize their vehicles' performance and durability.